The modern smartphone display is a veritable showcase of cutting-edge materials and chemistry. From the liquid crystal or OLED materials at the heart of it to the LEDs and optical films of the backlight structure, much of the display performance we take for granted comes from years of intensive development of the wide range of substances that go into the modern screen. Even though we’re literally in contact with them dozens of times every day, some display materials are rarely thought of: the cover glass and surface coatings that enhance the quality of the displayed image and protect the screen from damage, scratches, dirt, and grease. What exactly are they, what do they do and how do they do it?

Additional reading: MicroLED explained | Quantum Dots and QLEDs | Blue light filters

There are two general classes of materials to consider here: chemical coatings applied to glass to alter its surface properties, and specialized types of glass itself (which we’ll cover further below). We’ve already covered how coating display glass with various chemical films is done to reduce reflections, providing a natural segue to the types of coatings that keep your screen cleaner.

Display surface coatings

Two words come up regularly when you’re looking at such coatings: hydrophobic and oleophobic. The suffix -phobic derives from the Greek phobos, meaning “fear.” Just as a claustrophobic person has a fear of enclosed spaces, a hydrophobic coating “fears” water and an oleophobic coating “fears” oil. In both cases the coating effectively rejects wetting by these fluids.

Two words come up regularly when you're looking at such coatings: hydrophobic and oleophobic.

A drop of water on a hydrophobic material won’t spread out — instead, it beads up and rolls off. Teflon (polytetrafluoraethylene, or PTFE) is an example of a hydrophobic material; try sprinkling a few drops of water on your non-stick skillet, and you’ll see the sort of behavior I’m talking about. Oleophobic materials behave the same way toward oil, meaning oily or greasy deposits (like, say, your fingerprints) won’t stick to the surface, and can be quickly wiped away without a trace.

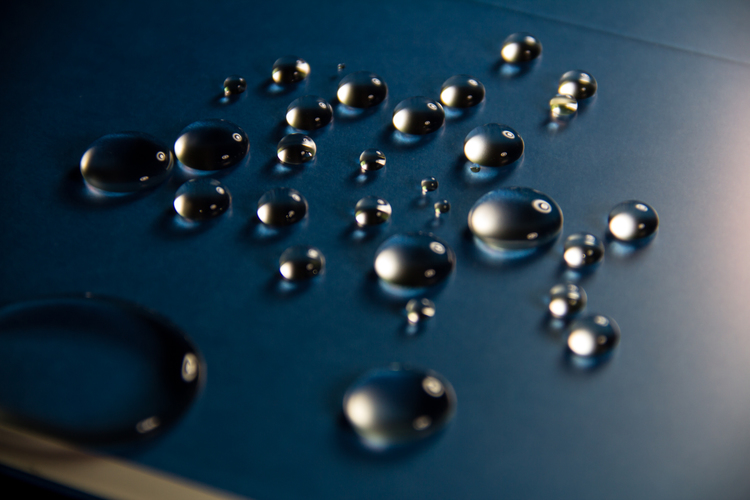

Quantum Coating, Inc. An oleophobic coating on glass, showing how oil beads up on the surface

Both types can be produced as transparent films on glass, and when used on the top surface of a screen obviously will help keep your tech clean. Hydrophobic films are often promoted as making glass surfaces “self-cleaning,” as water applied to them not only beads up and rolls off the glass, but it also tends to pick up any dirt on the surface and take that away with it.

Oleophobic coatings, of course, are just the thing for covering a touchscreen, which otherwise would quickly build up a grungy mess of fingerprints and greasy smears. Both types also make the surface fairly slick, an added benefit as it means that dirt and debris will tend to slide off the glass, rather than digging in and scratching it.

Tempered glass

What’s under those coatings is just as important as the coatings themselves. These days that usually means a tempered cover glass. Tempering refers to a number of processes which use heat cycling and/or exposure to various chemicals to harden and strengthen glass. Probably the best-known example of this in the smartphone and other LCD or OLED display markets is Corning’s Gorilla Glass, which is toughened through a proprietary process in which glass sheets are immersed in a 400-degree Celsius (752-degree Fahrenheit) bath of molten potassium salts.

Corning’s Gorilla Glass has become the standard of the industry — a very durable glass with a hard, scratch-resistant surface

The potassium ions diffuse deep into the surface of the glass, displacing smaller sodium ions. When the glass cools and contracts, the larger potassium ions generate compressive stress within the material, resulting in a much harder, tougher surface. Corning’s even produced a version of the glass with embedded silver ions, resulting in an antimicrobial surface — good if your phone gets passed around a lot. These days, such tempered glasses are the norm in the smartphone market. Along with the coatings mentioned earlier, they make for a screen which is both resistant to damage and easy to keep clean.

Protecting the screen from dirt and damage doesn’t have to be built-in at the factory, though. There are a wide range of aftermarket screen protector products, and not just the cheap adhesive plastic films. Today, you can find high-end glass screen protectors made from the same tough material as the phone’s own cover glass, with the same sorts of protective and anti-dirt coatings.

Today, you can find high-end glass screen protectors which themselves are made from the same tough glasses as the phone's own cover glass, and carry the same sorts of protective and anti-dirt coatings.

These provide superior optical clarity to plastic films, and result in the same sort of surface look and feel as the original. No matter how tough the glass is made though, there’s no such thing as a totally unbreakable or unscratchable screen. If your phone takes a hit strong enough to damage even these modern glasses, it’s clearly going to be far better to lose a $20 aftermarket protector than the phone’s actual display or cover glass. It’s cheap insurance that doesn’t detract from the appearance of the phone like those $1-2 plastic sheets.

Of course, whether you leave your original screen surface uncovered, or add a similarly coated surface, that coating itself isn’t invulnerable. Oleophobic and hydrophobic coatings are themselves pretty tough, and generally designed to last at least the typical two-year service life of your average smartphone. If you tend keep your tech longer, or you’re rougher on it than the average user, these coatings can wear to the point where they’re no longer providing much protection.

Looking after your screen

First, you should know how to maintain your screens so you get as much out of them as possible. Top of the list here is proper cleaning. The best methods for smartphones and other mobile devices will differ a bit from what you might have heard in the past. Larger screens such as TVs and monitors generally don’t incorporate touch, so they rarely have these same coatings that have become so common on our smaller devices. Because of that, the cleaners used for those big displays aren’t the best choice for phones. The classic advice for cleaning monitor and TV screens has always been to use isopropyl alcohol (ordinary rubbing alcohol) and a clean, dry, lint-free cloth.

Unlike TVs, using isopropyl alcohol to clean coated screens is a bad idea.

On coated smaller screens, alcohol is a bad idea. It can attack and dissolve many of the thin chemical films. Instead, keep the clean, dry cloth, but just spritz a little water (distilled is best) if you must, and let the self-cleaning properties of the coatings do the rest. Dirt, grease, and fingerprints should wipe right off. If you must use a chemical cleaner, look for one specifically labelled for smartphone or touchscreen use — they are formulated to be safe for these coatings.

If your screen has lost that new, slick feel, and water or oil fail to bead up when a few drops are sprinkled on the screen, your coating has sadly already been worn down to practically nothing. It’s not necessarily time to junk the phone, though (unless you’re looking for an excuse to upgrade).

If your screen has lost that new, slick feel, it's not necessarily time to junk the phone.

If you’re using a coated glass screen protector, the solution is simple. You can just replace it, and restore your surface to brand new (another reason to use a good glass protector). If not, there’s still hope. Several companies produce DIY oleophobic coating kits which can be used to restore your device’s fingerprint resistance and bring back that slick “new screen” feel (you may need to look for “anti-fingerprint coating” to find these).

Boxs-Certified A typical “do it yourself” screen coating kit

The application process is simple. After thoroughly cleaning the screen (many kits provide a special cloth for this), you just put a few drops of the coating fluid over the screen area, and spread it out into an even film (you need to do this right away, as the fluid dries fairly quickly). Leaving the phone alone for a while will give the new coating a chance to completely bond to the glass and form the hard, tough surface you’re looking for.

The new film may appear slightly hazy, but it can easily be buffed to the desired gloss. Applying several coats over the course of a couple of days will give even better results. These do-it-yourself treatments may not have quite the durability of some of the factory coatings, but once you’ve applied them you’ll find it fairly quick and easy to repeat as needed.

Dirt, fingerprints, and the occasional drop to the floor are all in a day’s work for the average smartphone. We can’t quite give them unbreakable, always-clean screens just yet, but thanks to a little chemistry we can come pretty close.

from Android Authority https://ift.tt/2rb0rvF

No comments:

Post a Comment